What is Freeze Drying?

And how does it work?How Freeze Drying Works

Freeze drying, also known as lyophilisation, is a highly effective preservation method that works by removing water from a product while keeping its structure, nutrients, and flavour intact. The science behind freeze drying is based on a process called sublimation.

Sublimation is when water changes directly from a solid (ice) to a vapour (gas) without passing through the liquid stage. This only happens under specific conditions, very low temperatures combined with low atmospheric pressure, conditions created inside a commercial freeze dryer.

Here’s why this is important:

In normal drying, heat causes ice to melt into water before evaporating, which can damage delicate structures, alter flavour, and degrade nutrients. But, in freeze drying, because the ice skips the liquid phase entirely, the product’s physical shape, texture, and chemical integrity are preserved. This controlled environment allows water molecules to leave the product without applying damaging heat, producing a lightweight, shelf-stable result that can be stored for years and rehydrated with ease. To achieve this, specialised equipment is required:

- Freeze Dryer: A large, insulated chamber that rapidly freezes the product and maintains a stable, low temperature during drying.

- Vacuum Chamber: Lowers the air pressure inside the chamber, enabling sublimation to occur efficiently.

- Condenser Coils: Trap and collect water vapour as ice, preventing it from reabsorbing into the product.

Benefits of Freeze Drying

Freeze drying is the ultimate solution for preserving quality, nutrition, and shelf life. By gently removing moisture without heat, it locks in vitamins, minerals, and natural flavours, while maintaining vibrant colour and texture. The result is a lightweight, shelf-stable ingredient that’s easy to store, transport, and use in powders, capsules, or ready-to-eat foods. Perfect for meats, offal, fruits, botanicals, and pet food, freeze drying supports clean-label, premium, and functional products while ensuring consistent quality at scale, giving brands the flexibility to innovate and meet consumer demand.

Freeze Drying Process

Step-by-Step

Step 1: Freeze

The product is rapidly frozen at very low temperatures. This locks in its natural shape, nutrients, and flavour, almost like hitting a “pause button” on freshness.

Step 2: Vacuum & Sublimate

The frozen product is placed inside a sealed chamber where the air pressure is reduced to create a vacuum. This prepares the environment for the ice to be removed without melting. Following, gentle heat is applied. Instead of melting, the ice crystals turn directly into vapour (a process called sublimation). This means the product avoids the damage caused by liquid water.

Step 3: Capture

The water vapour is drawn out of the chamber and refrozen onto cooling coils, leaving the product completely dry while retaining its structure. What’s left is a light, shelf-stable product that keeps its original flavour, colour, and nutrition. Because it’s so stable, freeze-dried food and powders are easy to transport, store, and use in finished products.

Applications of Freeze Drying

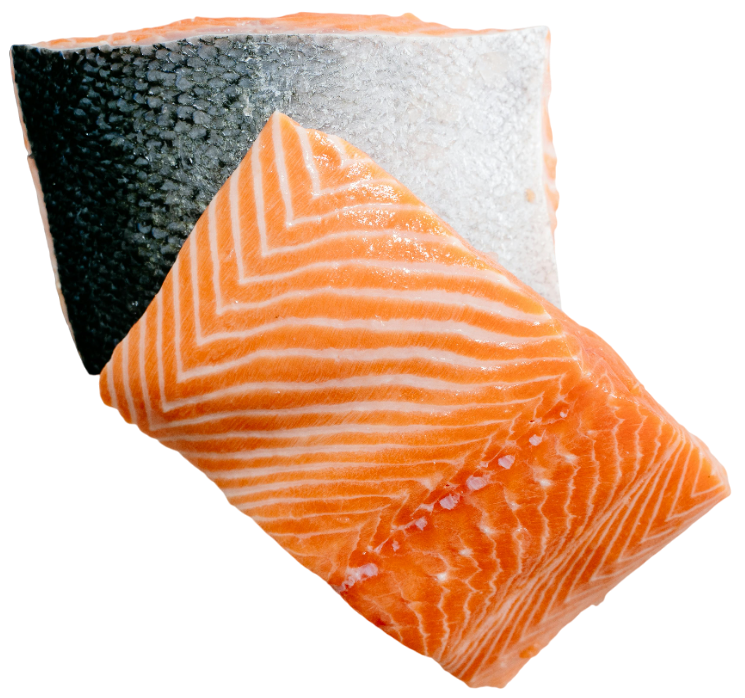

Food Industry

Freeze drying is widely used to create long-lasting, nutrient-rich foods without compromising taste, texture, or colour. Popular freeze-dried food applications include:

Fruits & Vegetables: Perfect for healthy snacks, smoothie powders, and baking ingredients while retaining vitamins, minerals, and antioxidants.

Herbs & Spices: Preserves aroma, flavour, and potency, ideal for gourmet cooking and convenient seasoning blends.

Whole Meals & Snacks: From camping meals to astronaut food, freeze drying offers lightweight, easy-to-store, and quick-to-prepare options.

Premium Pet Food & Treats: Maintains natural nutrition and palatability, catering to pet owners who want minimally processed, high-quality food for their animals.

Health Products

Freeze drying plays a critical role in producing high-quality, bioactive health products by locking in nutrients and active compounds. Common examples include:

Botanicals & Herbal Powders: Moringa, turmeric, lemon myrtle, and other plant-based powders retain their full nutrient profile.

Probiotics: Gentle freeze drying keeps beneficial bacteria viable for longer shelf life and effectiveness.

Protein & Superfood Powders: From whey protein to spirulina, freeze drying prevents heat damage and nutrient loss.

Beef Organ Capsules & Powders: Grass-fed liver, kidney, heart, and other organs are preserved with maximum bioavailability for health-conscious consumers.

Buy Wholesale

Buying wholesale with Agtech means accessing high-quality, sustainably sourced products in larger quantities at a competitive price. Wholesale options allow your business to keep stock costs low, maintain consistent product quality, and meet high customer demand without interruptions. Our bulk purchasing solutions include everything from ready-to-sell pre-packaged items to customisable quantities by weight, giving you the flexibility to choose what best fits your needs. With Agtech, you gain the benefits of reliable supply and transparent pricing, making wholesale a smart, efficient choice for growing your business.

OFFAL POWDER

DICED MEAT

CAPSULES

Confectionary

Partner with us!

At Agtech Freeze Drying, we provide custom manufacturing solutions for businesses looking to expand into premium, high-quality freeze dried products. Whether you’re a pet food company, nutraceutical brand, or food manufacturer, our facilities and expertise can help you bring market-ready products to life.

Contact us today to learn how we can manufacture freeze dried products for your brand.

Contact Us

We Work With Companies and Clients of All Sizes & Types

Need custom freeze-dried solutions for your business? Contact us today to learn more about our products, custom solutions, or to request a quote. Alternatively, you can book in a FREE 30 minute consultation.