Turn Waste Into Wealth: How Farmers Can Benefit from Freeze-Drying Produce

Every season, farmers generate vast quantities of produce that never reach the full market price. Whether it’s fruit and vegetables rejected for cosmetic defects, surplus harvests that exceed demand, or off-grade produce suffering from imperfect size or colour, much of this “waste” still has high nutritional value. What if instead of composting, discarding, or selling at a deep discount, you could transform that produce into premium powders, health food ingredients, pet nutrition additives, or other high-margin products?

Freeze-drying coupled with powdering offers exactly that opportunity: preserving nutrients, extending shelf life, and opening up new revenue streams. This blog walks through what freeze drying is, why it’s especially beneficial for farmers, how powdering works, real value-adding potential, sustainability benefits, and steps to get started.

What is Freeze Drying?

Freeze-drying (also known as lyophilisation) is a process of preserving perishable materials by first freezing them, then reducing ambient pressure and adding heat to allow the frozen water in the material to sublimate directly from the solid phase (ice) to the gas phase (vapour) without passing through the liquid stage. The result is a lightweight, porous product with nearly all moisture removed.

Key characteristics include:

-

Excellent retention of flavour, colour, aroma, and nutritional content

-

Very long shelf life without refrigeration

-

Great rehydration properties (if rehydrated)

-

Light weight and low volume once dried

This contrasts with conventional drying methods (sun-drying, air-drying, hot-air ovens etc.) that often degrade heat-sensitive nutrients, change colour, flavour, and texture, and may require ongoing cold storage or refrigeration for some perishables.

Why Freeze Drying Matters for Farmers: Key Benefits

Here are the core reasons farmers should consider freeze-drying their surplus or imperfect produce.

1. Reducing Loss & Waste on Farm

-

Fruits and vegetables are among the highest contributors to food waste because they’re highly perishable and often rejected due to appearance rather than nutritional or taste issues. For example, studies show a substantial amount of food waste comes from fruits & vegetables in the supply chain, including on farm and post-harvest losses (MDPI).

-

Imperfect or “ugly” produce often can’t be sold in fresh markets, but freeze-drying enables use of these for powdered ingredients or snack additives etc., increasing the usable yield.

2. Nutrient & Quality Retention

-

Freeze-dried produce can retain up to 90% of nutritional content in many cases, including vitamins, minerals, antioxidants, and phytochemicals, significantly higher than other drying methods (Chaucer Foods).

-

The process preserves flavour, colour, aroma better than many dehydrating or heat-drying techniques, making finished products more attractive to consumers and higher value.

3. Extended Shelf Life & Storage Ease

-

Once moisture is removed to very low levels, microbial activity, spoilage, and enzymatic reactions are drastically slowed. Products become shelf-stable.

-

No need for cold chain / refrigeration for many freeze-dried items, which reduces storage and logistics cost.

4. Reduced Transport & Logistic Costs

-

Because of substantial water removal, freeze-dried produce is lightweight; this lowers both shipping costs and carbon footprint.

-

Smaller volume means more efficient packaging, storage and transport.

5. Value-Adding & New Markets

-

Powdered food ingredients are increasingly in demand in functional foods, health & wellness, pet nutrition, ready meals, supplements, smoothies etc.

-

Consumers are paying premiums for clean label, natural, minimally processed, nutritionally dense products.

-

High value from ingredients that were previously considered low or no value (seconds, cosmetic rejects, surplus).

6. Sustainability & Branding

-

Reducing waste aligns well with sustainability claims and consumer preferences. Brands that can demonstrate less food wastage, upcycled ingredients, local production often get better market positioning.

-

Regulatory and retailer pressure is increasing for sustainable sourcing and waste reduction. Being able to use “waste” as an asset may open grants, incentives.

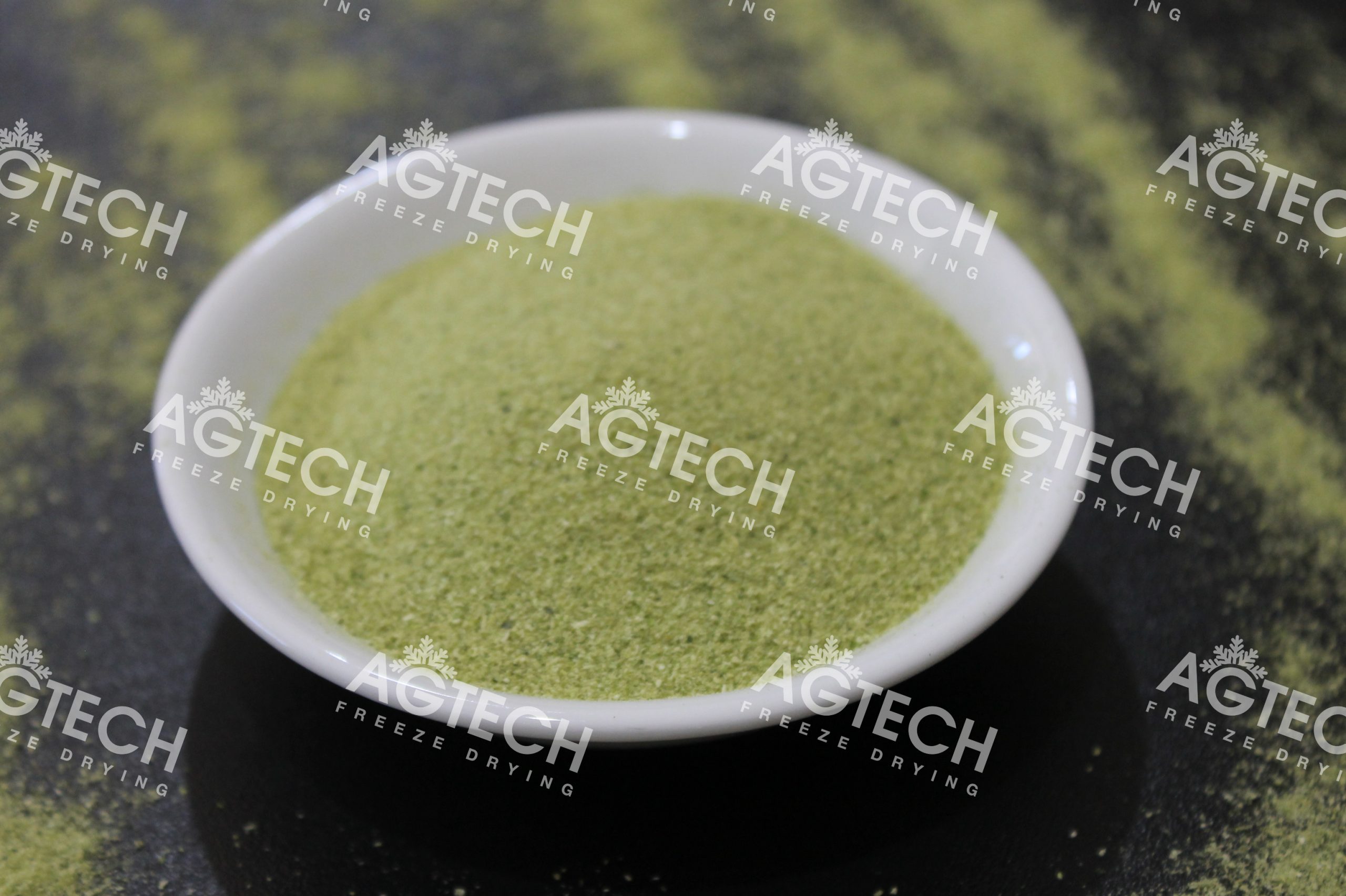

Powdering: Turning Freeze-Dried Produce Into Versatile Products

Freeze-drying itself is powerful, but combining with powdering magnifies its value.

What is powdering?

-

Milling the freeze-dried material into fine powder

-

Blending different powders (fruits, vegetables, botanical, organ etc.) for tailored nutritional or flavour profiles

-

Optionally encapsulating or mixing into formats for consumer use

Benefits of powdering:

-

Ease of packaging, storage, mixing into formulations

-

Higher margins: powder is easier to transport, ship, store, and use as an ingredient

-

Flexibility: Powders can be used in many products, smoothies, baking, pet food, seasoning, health supplements, broths etc.

-

Reduced spoilage risk vs fresh or even frozen produce

Market Trends

-

Growing global demand for natural, organic, clean label ingredients.

-

Trends in pet food and wellness are driving demand for organ powders, supergreens, bone broths, botanical & fruit powders.

-

Rise of snack bars, smoothies, functional foods that use small but potent amounts of freeze-dried powders for colour, flavour and nutrition.

-

Increasing focus on climate resilience, food security, reducing waste, freeze-drying helps farmers mitigate loss from extreme weather or market rejection.

Real Value Models

To help visualise, here are some hypothetical models (no numbers) to show how value flows, what could be turned into what, what markets might be accessed:

-

Farmer with excess blueberries or soft fruit: imperfect or surplus fruit can be freeze-dried, milled into powder, packaged or sold as ingredients to smoothie / beverage / baking ingredient firms.

-

Vegetable grower with leafy greens (spinach, kale) or herbs: freeze-dry then powder as “supergreen” powder; supplement or health food markets look for antioxidant rich leaf powders.

-

Grower/processor with root vegetables or tubers (e.g., turmeric, sweet potato): powdering after freeze drying yields high colour, flavour, and functional ingredient for spice mixes, natural colourants.

-

Fruit & veg producers with cosmetic rejects (e.g. “ugly fruit”): instead of primary market, shift to secondary markets through freezers/dryers + powdering, reducing loss, opening export or ingredient supply channels.

Steps for Farmers to Get Started

Here’s a roadmap for farmers considering freeze-drying and powdering:

Evaluate what you already have: Identify produce that is wasted (rejects, cosmetic defects, surplus), or perishable lots that are hard to move.

Partner with a freeze-drying service: If you don’t have equipment, look for contract freeze-drying, tolling, or third-party services. This lowers upfront investment.

Test small batches: Produce small trial lots to test the powder quality, flavour, colour, yield, packaging, and customer feedback.

Do market research: Who might want this product? Health food brands? Pet food? Nutraceuticals? Local shops or export markets?

Branding & packaging: Focus on clear labelling, highlighting attributes like “Australian grown”, “freeze-dried for nutrient retention”, “no additives” etc.

Develop sales channels: Direct-to-consumer via online stores, farmers markets; wholesale; bulk ingredient suppliers; export.

Ensure regulatory compliance: Food safety, traceability, labelling. For powders or ingredients, hygiene and possibly certifications matter.

Iterate and expand: Use feedback to refine product, packaging, flavour. Once proven, scale up batch size, diversify into other produce types.

For farmers, freeze-drying and powdering aren’t just niche technicalities, they’re real, practical tools to increase revenue, reduce waste, and build future-proof, sustainable operations.

By taking what might otherwise be lost, imperfect fruit, surplus harvests, by-products, and turning them into finished, marketable ingredients, farmers can tap into growing demand for clean, nutritious, Australian-made food and pet-nutrition ingredients.

The approach requires careful planning, test batches, branding, regulatory compliance, but the payoff can be substantial. If you’re ready to explore, start with identifying your waste streams, reach out to freeze-drying partners, and imagine what your farm might look like if nothing useful goes to waste.